Respiratory Protection Program

The Respiratory Protection Program is in place to decrease potential risks to employees who may be exposed to breathing hazards. It is mandatory for all employees who use respirators to be fit tested every two years.

Respiratory Fit Testing FAQs

Fit testing is the only way to guarantee that the mask you are using is appropriate for your face shape and for the tasks you need to complete. Not only is fit testing a way to protect yourself from contaminants at work, it is also a legislated requirement mentioned in Alberta Occupational Health and Safety Code.

As an employee exposed to respiratory hazard, it is your responsibility to participate in relevant training, review Hazard Assessment Control Forms, Safety Data Sheets, and Standard Operating Procedures, report unsafe conditions, get fit tested, and report any changes to your health that would affect respirator use to Occupational Health. You also are responsible for maintaining, inspecting, and storing respiratory protective equipment. For more information on employee responsibility, please see the Respiratory Protection Program.

As a manager, you are at the front line of work and have unique responsibilities regarding fit testing. You need to ensure that you have engineering and administrative controls in place if your employees are working with respiratory hazards. You are responsible for ensuring that employees are fit tested, and the correct respirator is provided as per the fit test record. For more information on manager responsibility, please see the Respiratory Protection Program.

Surgical masks are fabric or paper masks that catch droplets or particulates from the wearer’s mouth. These are ideal for conditions where you don’t want to contaminate something with your droplets, but this mask is not intended to filter out any particulates, including dust, airborne disease, or smoke to protect you.

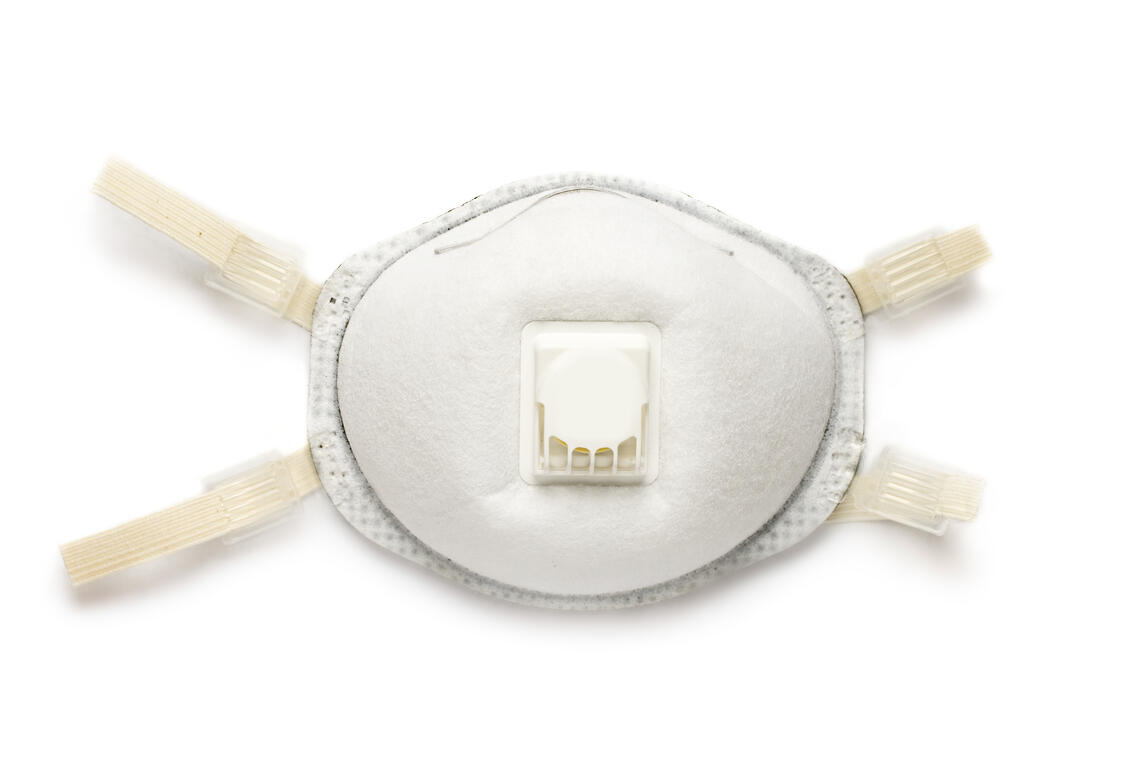

N95 respirators are disposable and filter at least 95% of airborne particulates. These respirators are not resistant to oil, nor provide protection for exposure to vapours. These respirators are tight fitting and are intended to protect the user against airborne particulate.

Half face reusable respirators are plastic respirators that make a tight seal around the face. Cartridges can be added to these respirators to provide protection against things like particulates, certain organic vapours, solvents, and certain acid gases. These respirators can be reused and need to be inspected and cleaned regularly.

For a visual representation of the differences, please see below.

Cartridge change out schedule depends on many different variables, such as what humidity a person works in, how much of a substance a person is using, how often the person is using a substance, and other factors. To find out what cartridge change schedule would work best for yourself or your team, please contact us to find an appropriate schedule for your task.

Surgical Mask

Surgical masks are paper masks that catch particulates from the wearer’s mouth. These are ideal for conditions where you don’t want to contaminate something with your droplets, but this mask is not intended to filter out any particles from the air.

Colourbox.com / Supplier #222341

N95 Respirator

N95s are disposable and made to filter at least 95% of airborne particulates. These respirators aren’t resistant to oil. These respirators are intended to protect the user against airborne particulate.

Colourbox.com / Supplier #2758

Reusable Respirator

Reusable respirators are plastic and make a tight seal around the face. Cartridges can be added to these masks to provide protection against things like particulates, vapours, and gasses. These respirators need to be inspected and cleaned.

Colourbox.com / Supplier #1354