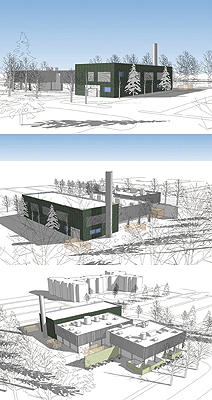

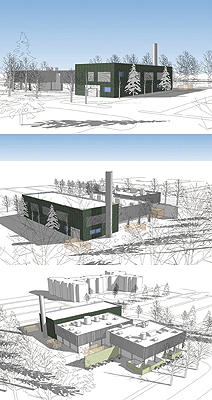

Views of the cogeneration plant with Cascade Hall in the background.

Nov. 1, 2008

Views of the cogeneration plant with Cascade Hall in the background.

The University of Calgary is converting its central heating and cooling plant into a cogeneration facility that will cut CO2 emissions by 80,000 tonnes annually, far below both national and global standards.

The conversion, expected to be completed by October 2011, will reduce CO2 emissions by about 50 percent from today’s levels—37 percent less than Canada’s Kyoto commitment of six percent below a 1990 baseline and exceeding Alberta Environment standards for natural gas-fuelled power generation.

“Being a leader in sustainability means taking the little—and the big—steps,” says U of C President Harvey Weingarten. “This is a significant step in our long-term goal to become a carbon neutral campus.”

Cogeneration, also known as combined heat and power or CHP, is an efficient, clean and reliable approach to generating power and thermal energy from a single fuel source. That is, it uses heat that is otherwise discarded from conventional power generation to produce thermal energy.

The $48-million investment will provide the university with a source of clean, cost-competitive electricity and pay for the $18 million in incremental costs (going the cogeneration route versus simply installing a new boiler) with an estimated $3.5 million annually in operating cost savings.

For more than 40 years, the university has met its demand for energy by the traditional approach of purchasing electricity from the power company and acquiring natural gas to burn in boilers to produce heat required to serve the campus.

“The existing equipment is now at the end of its service life and is undersized to meet the requirements of the growing campus footprint,” says Ian Thompson, program manager in the Capital Program Office. “[Cogeneration] is a very popular technology and many campuses across Canada have adopted it. It’s the smartest and most sustainable option right now.”

The new facility will take the natural gas normally used to produce heat and use it to run a gas turbine instead that will generate electricity to campus. The waste heat produced by the turbine will be used to heat the campus. By using this waste heat, a total energy efficiency of 75 percent can be achieved. This compares to around 49 percent efficient use of natural resources to produce electricity and heat in the conventional manner.

In all, new facility will generate 12 megawatts of electrical power—enough electricity to power the equivalent of 12,000 homes. It will also be quieter, reducing total noise to levels significantly below City of Calgary standards.

The cogeneration facility is part of the U of C’s commitment to sustainability and of the campus’s $1-billion capital expansion.

Natural gas is injected into the combustion chamber of a gas turbine. This natural gas is mixed with fresh air in the turbine and burned to produce motive force. The rotating shaft of the gas turbine is connected directly to an electrical generator that will produce about 12 megawatts of electric power that will be distributed through the campus systems.

The hot exhaust gases that would normally be discharged to the atmosphere still contain a significant amount of energy. In cogeneration, this energy is used to provide heat. In the case of the university, these hot exhaust gases will be channelled through a waste heat recovery unit that will generate hot water at 205°C. This water is pumped to the main campus buildings through a network of pipes in an underground tunnel system. It is then used in the buildings to produce space heating and hot water.

This single cogeneration unit will be capable of meeting all of the heating requirements for the main campus and will effectively ‘retire’ the existing equipment.