The Research

3. LCA of existing operations

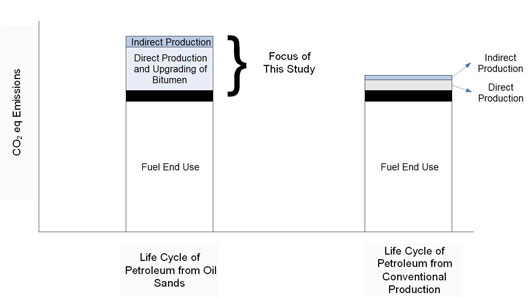

A good starting point for assessing the impacts of oil sands operations is to conduct an LCA of current operating facilities in Alberta. This assessment would allow the comparison of mining versus in situ extraction operations. The metrics for analysis would start with a breakdown of the capital and operating costs. While high level economic data is available for most currently operating facilities, there is a lack of detailed financial data. In order to assess the environmental impacts of these operations, detailed economic data is required. In addition, the flow of material should be tracked. This should include how much material is required, the distance that the materials are shipped and by which transport method. The third step in conducting this analysis is to assess the amount of energy required in each stage of the operation. For example, roughly 1 GJ of natural gas energy is required to produce 1 barrel of synthetic crude from the in situ extraction phase. For the mining extraction phase the energy requirement is roughly 0.25 GJ of natural gas. In addition, electricity is required (roughly 0.0083 and 0.0147 GJ respectively). However, additional upstream energy is required to produce products consumed in the construction and operation of the oil sands extraction site, as well as the energy required to transport those materials. Once the cost, energy and material flows have been accounted for, the environmental impacts can be assessed. Due to increasing concern about the impacts of climate change, the GHG emissions from all phases of the life cycle should be calculated. These emissions are very different between in situ versus mining operations, as well as for different choices made in terms of fuel choice, material selection, etc. The following graph shows a description of the focus for this study. Preliminary estimates show that accounting for the supply chain emissions from the production and upgrading of bitumen increase the total production/upgrading emissions by over 25%.

Industry interaction is essential to providing decision support tools that are relevant and timely for the industry. We will work with our research partners to understand the technologies that are used today and those that are being developed for future deployment. The data collected from companies in Alberta will be used to supplement the output from the models discussed in previous sections.

4. Prospective Technologies

Life cycle methods have generally been applied to existing technologies, but such techniques can also be employed prospectively, to assess and compare the life cycle costs and impacts of technologies now under development. Prof. MacLean and colleagues have conducted such studies (e.g. Spatari et al. 2005).

Researchers will work with scientists, engineers, and members of the business community who are developing new oil sands technologies to develop and refine techniques for prospective LCA. These techniques will enable systematic estimates of the life cycle impacts of oil sands development in the period 2020 and beyond. Perhaps more importantly, these techniques will help the prioritization of research and development activities by identifying technologies, or optimal combinations of technologies, that would provide particularly large life cycle benefits.

5. Land Use Impacts

There are currently over 100,000 km of linear developments in the Al-Pac FMA, with an average density of 1.8 km/km2. If forestry activity persists at current levels, and if the energy sector expands at expected rates, the average density of linear developments will increase to over 5.0 km/km2. This trend would have negative effects on many species. For example, woodland caribou habitat quality in the study area has declined by 23% over the past several decades, with further declines expected if trends in industrial development continue.

Considering the operation site, it appears that surface mining techniques disturb much more surface area than in situ operations. However, this does not take into account the fact that 4 times as much natural gas is required per barrel of bitumen for the in situ process. This means that 4 times as much natural gas infrastructure is required as well. One of the biggest impacts of land use is the fragmentation of land. Therefore, surface area is less important than the linear distance within a given area.

A more thorough analysis that includes the impact of land fragmentation is required to provide a more robust comparison between the two options for extracting oil sands resources. This analysis could be carried out by obtaining remote sensing data images for the Alberta area. A tool such as IKONOS could provide satellite data at various levels of spatial resolution. This data could be used to create land cover and land use maps. Metrics could be determined to measure the impact of fragmentation on the area of interest. Software tools such as FRAGSTATS would interpret the land use/cover maps to provide such results. The Wilderness Society Study used ArcView 3.2 and RoadNET.

Several studies in Alberta using remote sensing for the natural gas and oil industries have been found. These include the use of remote sensing for monitoring gas pipeline right of ways. However, a study that looks at the fragmentation of land in Alberta due to natural gas and oil operations has not yet been found.

7. Replacement of Natural Gas with Other Fossil Fuels

The price and availability of natural gas in North America has forced energy intensive industries to reassess their fuel supply options. This is especially true of the in situ oil sands operations in Alberta which consume large quantities of natural gas (roughly 1000 standard cubic feet per barrel of synthetic crude). We will apply the LCA model to investigate the implications of using coal to supply heat, electricity and hydrogen to oil sands operations as an alternative to natural gas. Coal is an inherently dirty fuel and rail systems are costly to build. However, the fuel itself is relatively cheap, abundant and nearby. In addition, technologies exist today that minimize many of the environmental problems associated with this fuel. In addition to the capture and removal of conventional pollutants such as NOx and SO2, the potential for CO2 capture and storage exists.

Applying the life cycle analysis framework to this problem is essential as the upstream and indirect impacts of these two options are non-negligible. The comparison between these two options will include economic and environmental impacts of the entire infrastructure required to operate these facilities. This includes the impacts of extracting and shipping the fuels from their source to Northern Alberta, as well as the transport of materials, construction, and operation of energy conversion facilities close to the oil sands operations. This analysis will be similar in structure to that conducted by one of the project members in this proposal.

8. Nuclear in the Oil Sands

The use of nuclear energy in the oil sands will be considered as an option to offset rising natural gas prices and rapidly growing CO2 emissions. The monetization of these benefits may represent a substantial incentive to commercial application of nuclear technology. The application of nuclear technology to offset natural gas use and CO2 emissions from oil sands production and bitumen upgrading operations could produce significant public economic and environmental benefits.