PPG RESEARCH AREA

The main research areas of the group are: Polymer Nanocomposites Polymer Blends Extrusion Visualization of polymer flow Polymer Adhesion Polymer Interfacial Tension Material Properties of Polymers

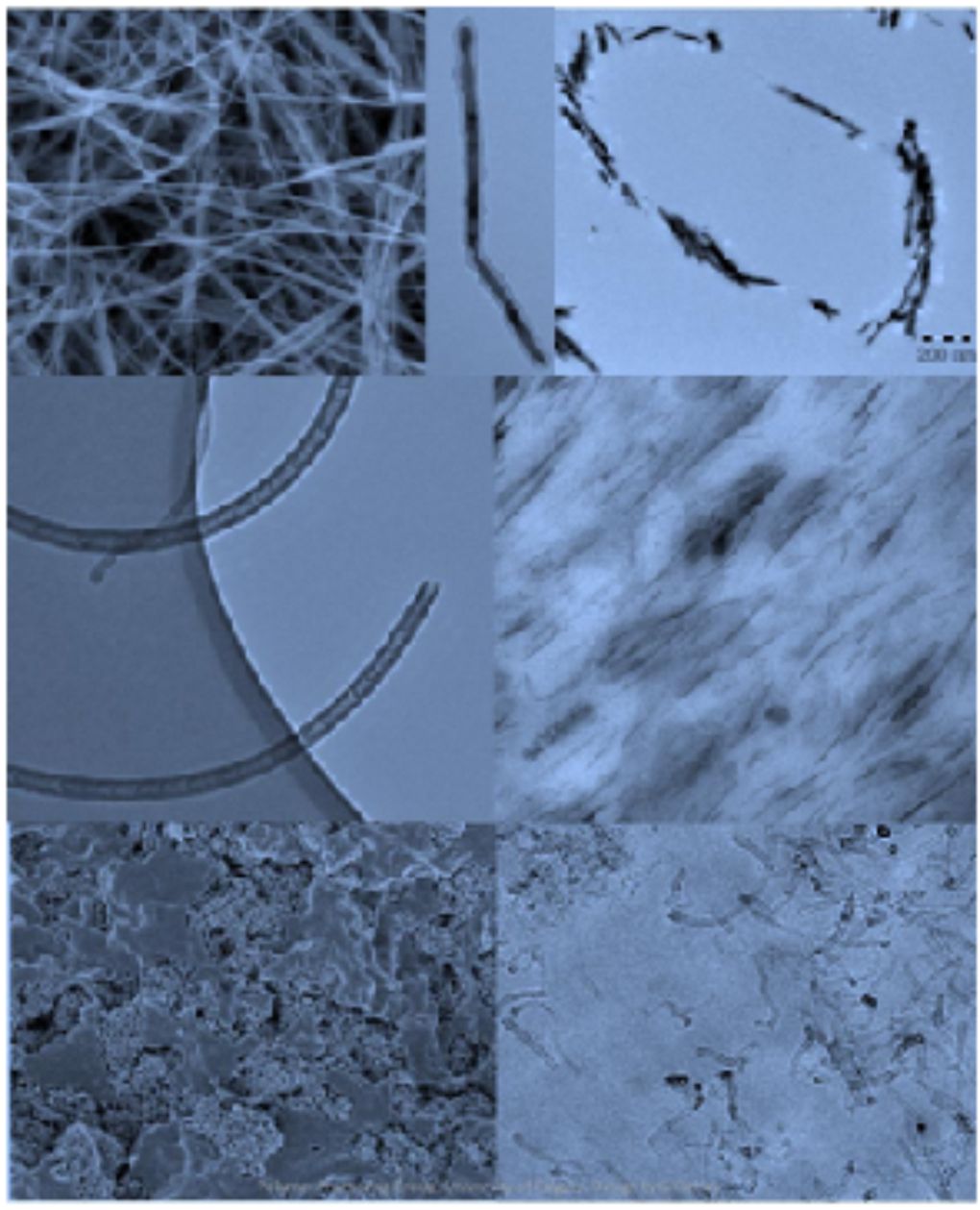

The group has made polymer nanocomposites using specialty metal nanofillers produced in-house. These "nanowires" are made in-house using a template-directed method which allows us to tailor the size and properties of the nanofiller. When combined with polymers, they have unique properties that are suitable for smart and advanced materials. It has been found that these materials offer key combinations of properties not available in single-phase materials. The incredible amount of interfacial area that is available in nanosized materials can lead to novel properties previously unattainable via traditional composites. Other studies of current interest for the group are related to the understanding of properties and processing of polymer nanocomposites made of immiscible polymer blends and nanofillers like carbon nanotubes, carbon nanofibers, graphene, and nanoclays. This is a very exciting, challenging and multidisciplinary area of the group that offers great opportunities for academic and industrial research. Below are some electron micrographs of different research projects in this area developed by our group over the last years.

The group is also involved in studying the fundamentals of extrusion and applying chemical engineering concepts to the extrusion process. Fundamental chemical engineering concepts like heat transfer, mass transfer, reaction and mixing have not been applied to what is essentially a chemical engineering process - screw extrusion of polymers and polymer blends. Previous work in this area has not attempted a unifying treatment of the twin-screw extrusion process using chemical engineering.

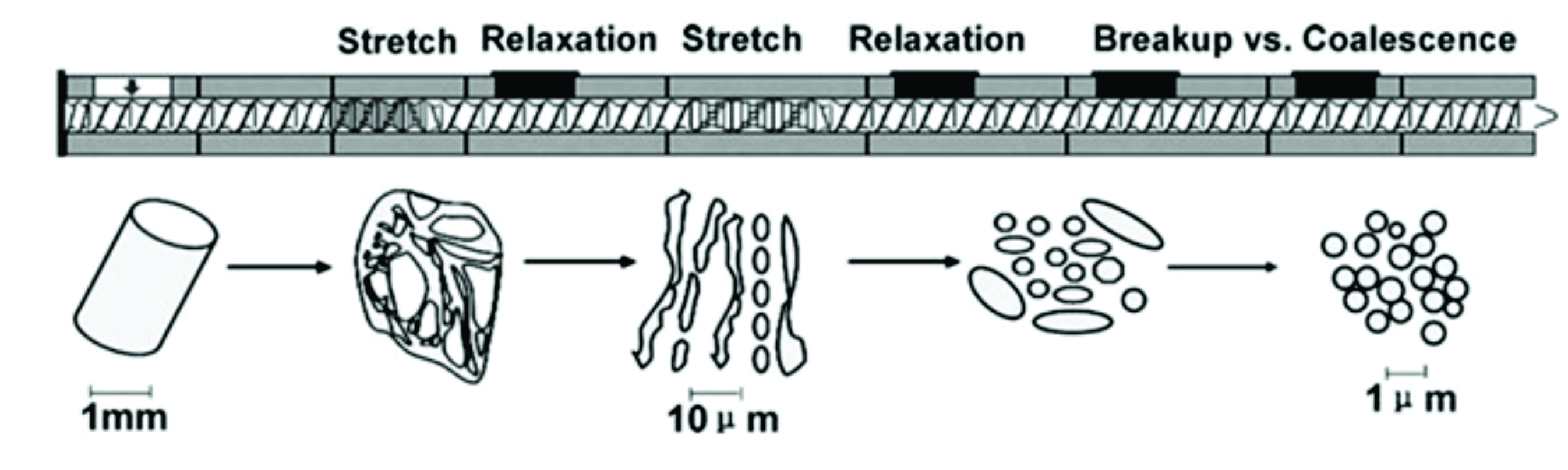

The final properties of polymer blends depend on their morphology, which is in turn controlled by the blending process. It is crucial to understand the mechanisms that control the incorporation of one polymer into another and its relation to the final distribution and properties of the blend. The group has laid out the basic mechanisms involved in the morphology development of a polymer blend: i.e. the breakup and formation of particular structures of a polymer material inside another polymer. The group is doing contributions to the visualization of melting, deformation, and breaking up of polymers during melt mixing process. Currently, we are modeling deformation of viscoelastic materials and using model experiments to understand the fundamentals. The effects of coalescence and interfacial reaction on the stability of polymer blend morphology are studied.

The group has built two new miniature mixer designs to analyze specialty materials available in small quantities (2 grams or less). These custom-designed mixers allow us to synthesize blends and nanocomposites that match those made in larger industrial scale extruders and batch mixers.