Research

A. Nano-Micro-Meso Mechanical Machining

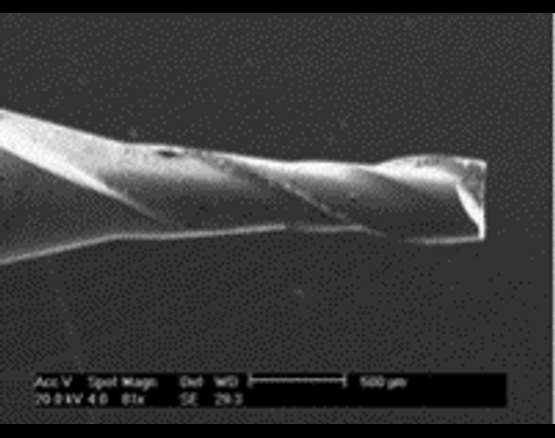

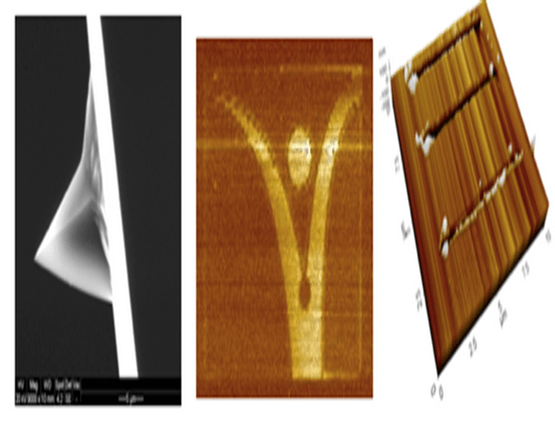

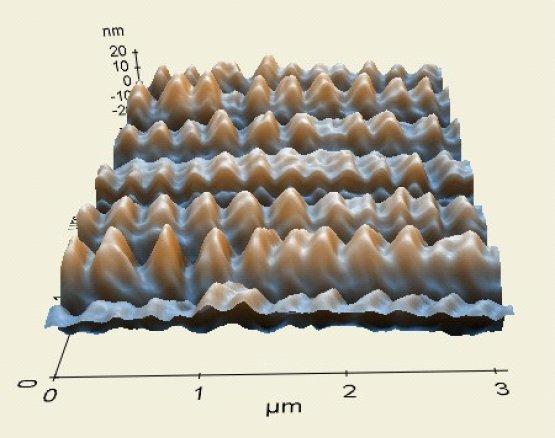

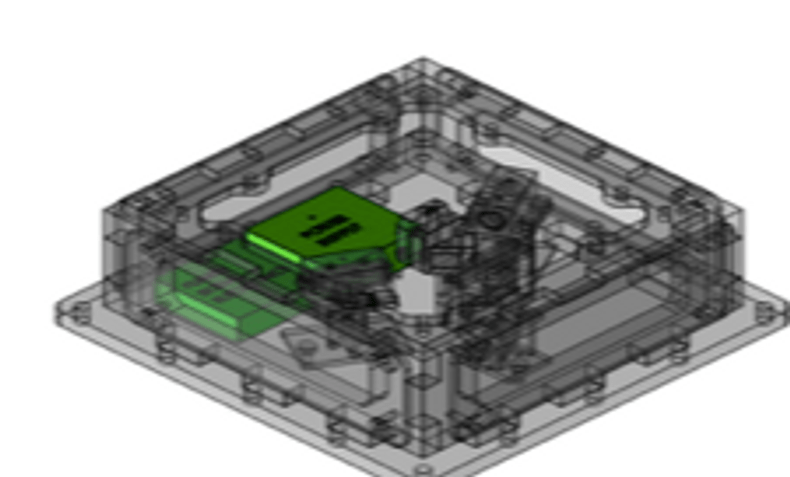

The miniaturization of components, to accommodate the demand for shrinking component size with high accuracy, is becoming increasingly important for various modern industries such as aerospace, biomedical, electronics, environmental, communications, and automotive. With the recent widespread use of nano and micro-electro-mechanical systems (NMEMs), the implications of the technology are far reaching in the enhancement of our quality of life and in economic growth. The common methods of manufacturing miniature components have been based on semiconductor processing techniques, where silicon materials are photo-etched through chemical processes. However, the majority of these methods are limited to a few silicon-based materials and to essentially planar geometries. Furthermore, the demands to interface nano and microscale components by means of packaging and handling to the macro world have become increasingly important. To overcome the limitations imposed by the existing micro-meso fabrication technologies, we propose to utilize the subtractive ultra-precision nano, micro-machining setup to fabricate nano-micro-mesoscale components that have complex three-dimensional sculpted shapes and are made from a variety of metallic alloys, composites, polymers, and ceramic materials at a fraction of the cost of other micro-fabrication methods. We utilize the ultra-precision machining centre and the atomic force microscope (AFM) to fabricate desired shapes.

Specific Tasks:

- Prediction of Micro & Nano Cutting Forces

- Monitoring of Micro Machining Processes through Sensor Fusion

- Tribology

- Vibration and Laser-Assisted Machining

- Adaptive Control

- Robust Chatter Stability

- Machining of Novel Materials

- Dynamics Testing of Micro-Systems

- Substructure Coupling of Substructures

- Micro Mold Fabrications

- 5 Axis Micro Machining

- Nano Patterns to Reduce Friction

- AFM-based Machining

- Composite Machining

Micro Cutting Tool

AFM Probe Based Machining

Brass Cage, Fabricated with 5axis Kern Micro System (2mm x 2mm)

AFM generated nanopatterns

B. Nanocomposites / Sensors and Monitoring / Printed Electronics

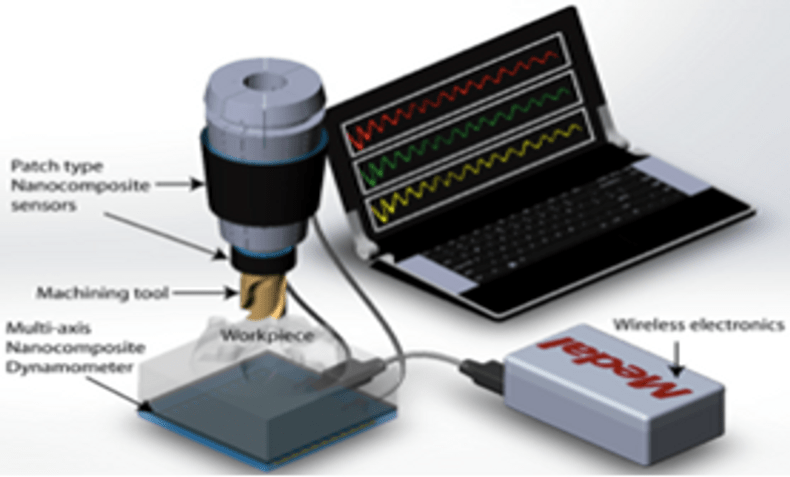

Highly accurate, miniaturized components comprised of a variety of materials play key roles in the future development of a broad spectrum of products such as wearable devices, lab-on-chips, chemical and biological particle screens, subminiature actuators and sensors, and more. With the advent of the Internet of Things (IoT) and Industry 4.0, the development of wearable, cost-effective, and reliable miniature devices is vital to improving quality of life and enhancing economic growth. The broad commercialization of nanocomposite products has been limited due to an inability to manufacture accurate 3D components in an economically efficient manner. It has been further limited by a lack of effective packaging and interfaces between nano-, micro-, and macro domains. The goal is to overcome the limitations posed by existing fabrication technologies. We will accomplish this by deposition of metallic nanopowder alloys to manufacture multifunctional nanocomposites. These processes do not require the expensive setups of photolithographic methods, nor are they as environmentally unfriendly as the electrochemical machining process. The nanocomposite manufacturing process can be achieved through the depositing of conductive, insulating, sensing, and actuation materials onto polymeric substrates. This approach allows for the rapid fabrication of micro- and nano-scale components using a variety of materials at a fraction of the cost of conventional methods.

Specific Tasks:

- Sensors for mechanical, chemical, and environment

- Actuator developments

- Industry 4.0 / IoTs / Cyber-Physical Systems

- Artificial Intelligence

- Mechatronics

- Smart systems

- Printed electronics

- Wearable devices

Multi-Sensor Enabled Smart Factory

Multi-Axis Optical Force Sensor

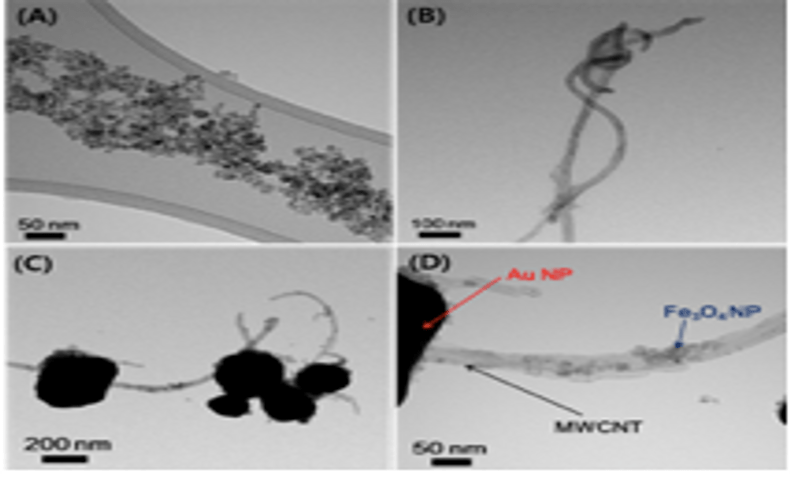

TEM Images of (A) Iron Oxide NP, (B) MWCNT, (C) IA-CNT (low mag) and (D) IA-CNT (high mag)

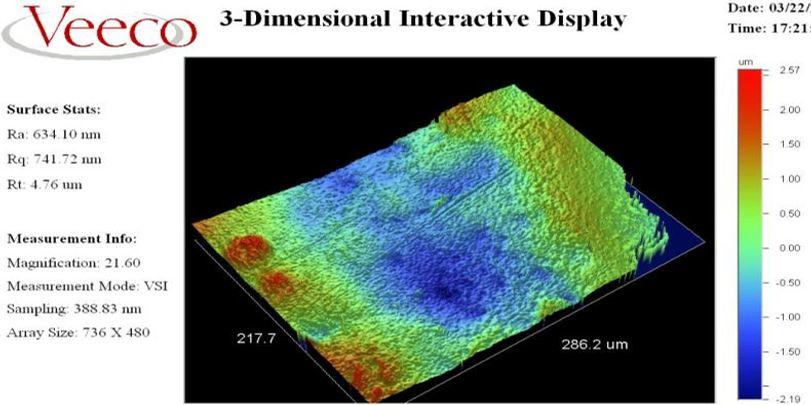

Wood Fibre Polymer Surface

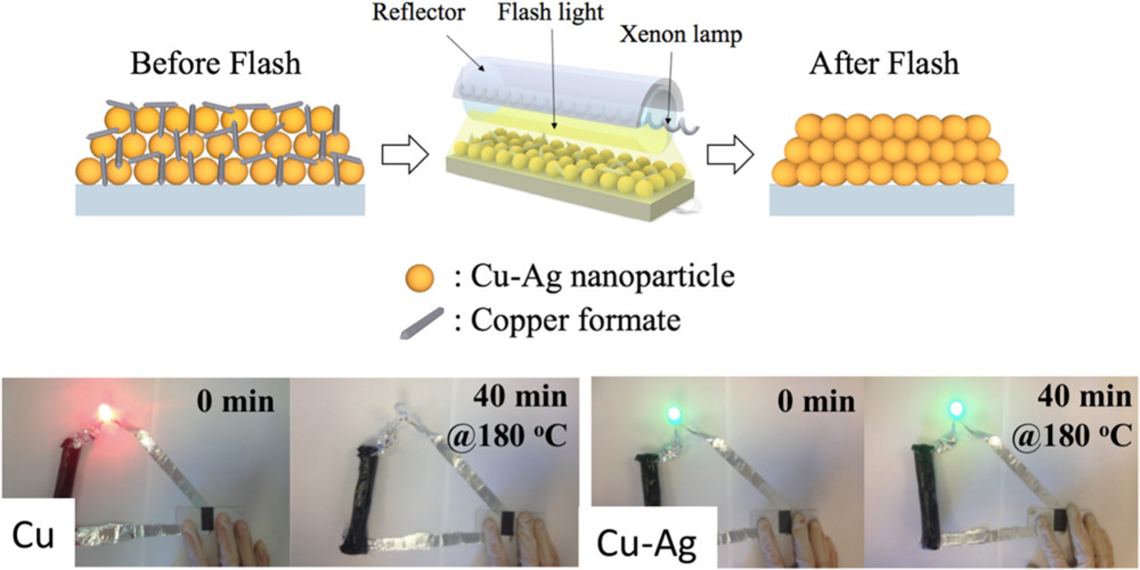

Sintering of Conductive Inks

C. Pipeline Engineering

Pipeline Engineering Centre at University of Calgary: www.ucalgary.ca/pec

Specific Tasks:

- Leak Detections – Computational Pipeline Monitoring using AI

- Non-destructive Tests – ultrasonic, magnetic flux leakage (MFL), non-contact

- Composite Coatings

- 24/7 Sensing and Monitoring

- Drag reductions

- Integrity Analysis

- In-line Inspection Tools

- Stress/Strain monitoring

D. Experimental Vibration, Substructure Coupling, and Joint Dynamics Identifications

Coupling today's manufacturing industries are faced with many challenges to deliver high quality, flexible, cost-effective products. Reconfigurable Manufacturing Systems (RMS) offers a rapid change in system configurations, machines, and controls to adjust flexible demands. One of the key challenges of RMS is to achieve high stiffness and damping of machine tool structures. Therefore, the prediction of modular structure dynamics is important especially for machining operations where identification of chatter-free cutting conditions is paramount for productivity. In this study, a method of assembling known dynamics of substructures, namely spindle-tool holder with an analytically modelled end mill, is investigated through receptance coupling and model updating approaches. The classical receptance technique is enhanced by proposing a method of identifying the joint dynamics which include both translational and rotational degrees of freedom. The identification of joint dynamics can be applied to the prediction of RMS. The technique can also be applied to Finite Element methods to simulate the machine tool dynamics prior to the actual building of machine tools to optimize the dynamic performance of machine tools.

Specific Tasks:

- Experimental Modal Analysis

- Identification of Joint Dynamics

- Vibration and Shock Isolations

- High-Frequency Bandwidth Measurement of Micro Cutting Forces

- Monitoring of Micro Machining Processes through Sensor Fusion

- Verification of FE

- Instability Analysis

- Flow-Induced Vibration & Pulsations (i.e. pipeline vibration)

- Bio-Dynamics (human joints)

- Identification of Intervertebral Disc Dynamics

E. Micro Engineering Applications

E1. Alternative Energy Applications

The ever-growing global energy demand, depletion of oil reserves and escalation of pollution in urban areas have increased demand for feasible low-cost renewable energy resources.

Dye-Sensitized Solar Cells (DSSCs)

Dye-sensitized solar cells (DSSCs) offer the advantages of increased absorption of visible light, high-efficiency potential, lower energy usage, low-cost manufacturing processes, colourable designs, and light-weight material options. DSSC cells are capable of operating in low-light environments and are suitable for indoor uses. We are in process of utilizing innovative designs and manufacturing processes to improve the efficiency and model the DSSCs. We utilize a potentiostat/electrochemical impedance spectroscopy to analyze the system.

Direct Methanol Fuel Cells (DMFCs)

Direct methanol fuel cell (DMFC) is becoming increasingly popular especially for small electronic devices which draw power from a methanol-oxygen reaction. Unlike PEMFCs which use hydrogen, DMFCs work with liquid methanol and thereby eliminates the onboard hydrogen storage problem as well as be able to operate at moderate temperature compared to solid oxide fuel cells (SOFC). In addition compared to conventional batteries, methanol has a higher energy density than even the best lithium-ion batteries. We are currently optimizing different bipolar geometries and modelling the entire DMFC system.

E2. Micro Pumps

One of the fundamental components of fuel cells or fluidic devices is micro-pumps. A micro-pump provides fuel cells with a precisely controlled flow of fluid or gas. Micro-pumps can also be used for other applications such as bioscience research and medical devices such as lab-on-chip (LOC), drug delivery, and other point-of-care (POC) applications. The cost-effective, disposable, and bio-friendly characteristics of the polymeric micropumps are also ideally suited for these applications. We have been developing micropumps and manufacturing small volume prototypes.

E3. Nanocomposite Applications

Electromagnetic Interference Shielding - Through use of CNT based nanocomposites

Sensor Networks - Through use of CNT based nanocomposites

E4. Development of Novel Sensors

- Inclinometers for fracking and CCS Monitoring

- Force, strain, stress sensors

- Temperature and chemical sensors

F. Applications

i. Directional Drilling/Subsurface Monitoring

ii. Alternative Energy - Flexible Aluminum Batteries

iii. Green Energy – Partial Upgrading and Remediation

iv. Erosion - In Pipelines and Petroleum Processing

v. Micropumps and Other Micro Applications