Research

Polymer Nanocomposites and Polymer Blend Nanocomposites

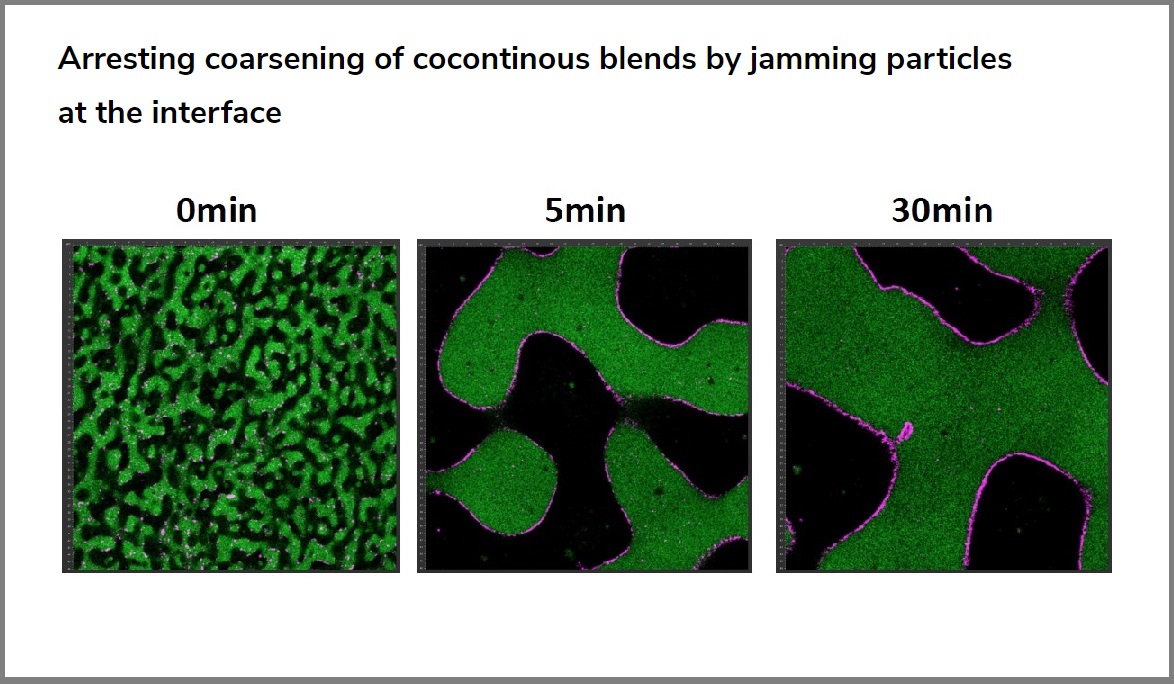

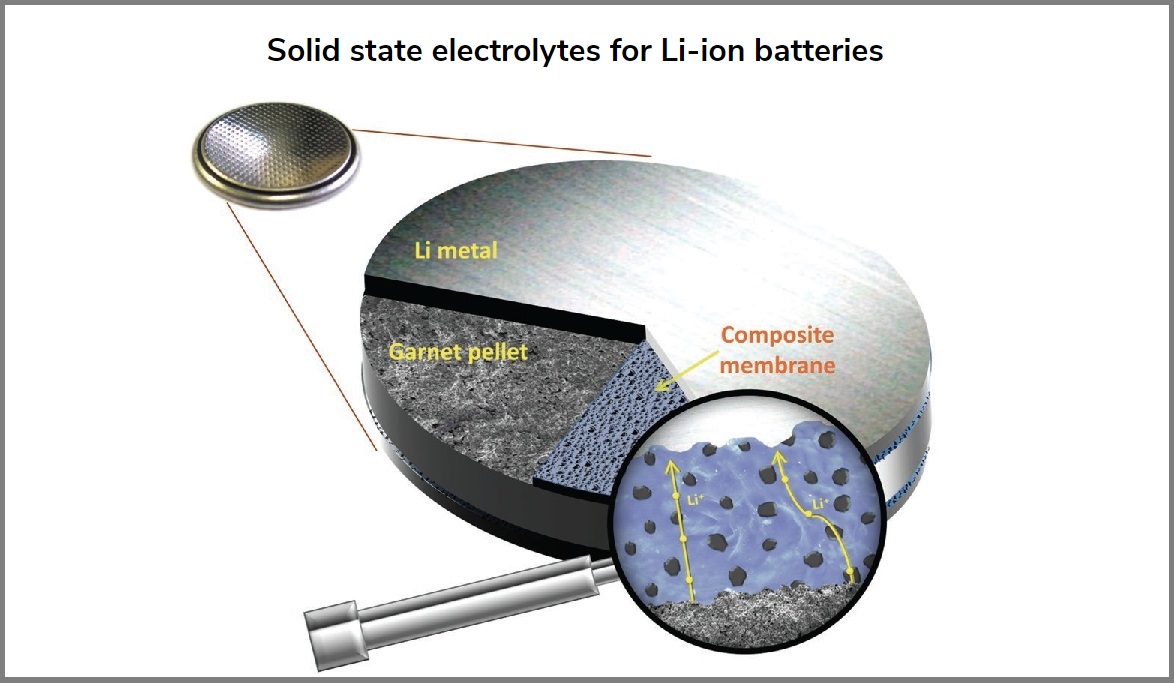

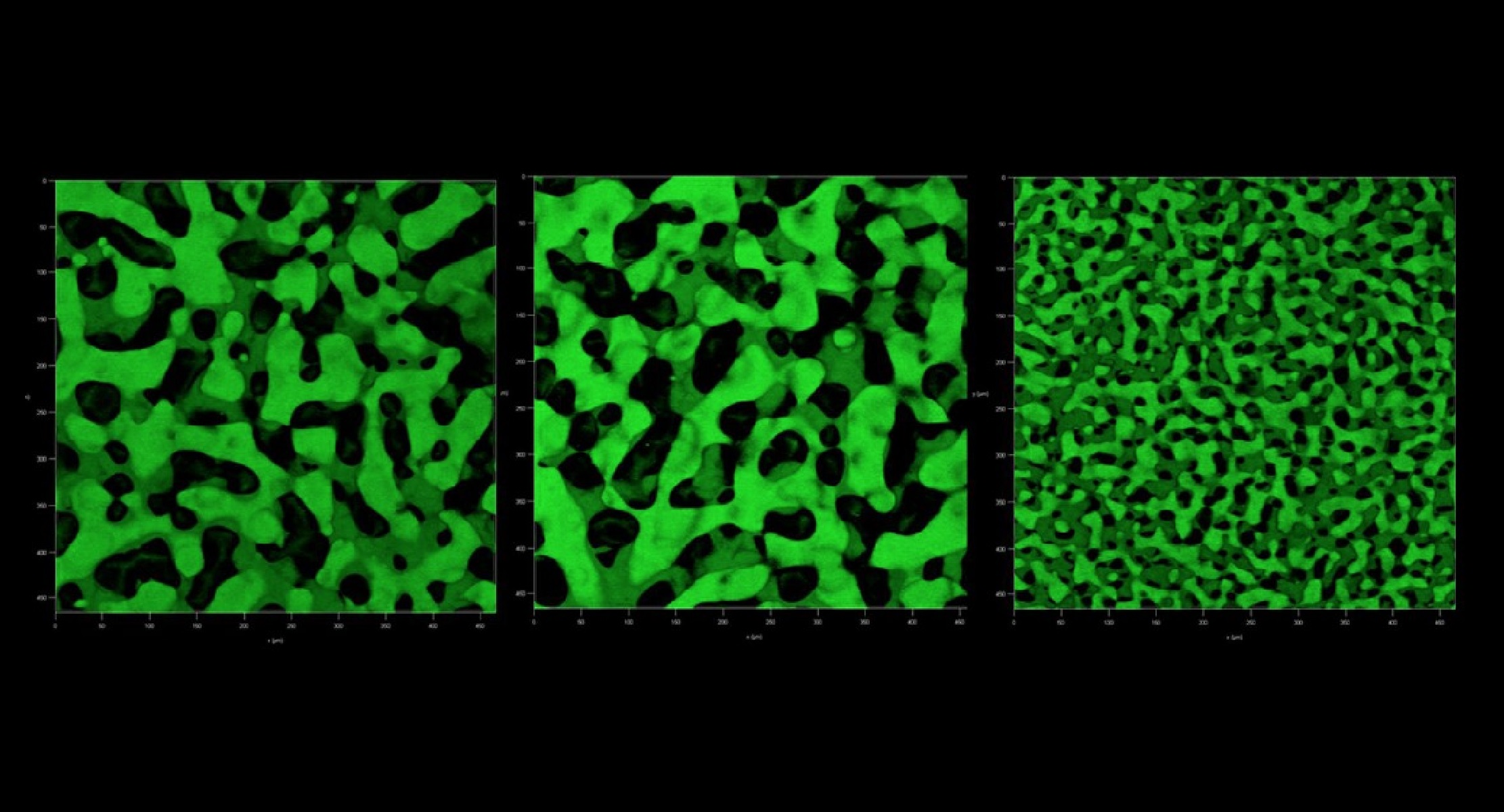

The objective is to develop novel theoretical, computational and experimental techniques for the discovery and analysis of polymer blend nanocomposites. We seek the relationship between the nano and micro-scale structural variables and macroscale physical and mechanical properties of compatiblized polymer blends and polymer nanocomposites. Quantification of the interactions in polymer nanocomposites is essential for predicting their morphology and macroscopic properties. However, this quantification is an ongoing challenge due to the lack of a systematic approach that allows measurement of nanoparticle (NP)-polymer and NP-NP interactions. We measure these interaction by colloidal probe atomic force microscopy (CP-AFM). This approach can be used to predict the dispersion of NPs in a variety of mediums including polymers and solvents. To obtain qualitative and quantitative information of the microstructural evolution of these systems during well defined macroscopic flow fields, we employ high temperature confocal-rheology setup. Combining confocal microscope with a rheometer enables imaging of sample morphology in 4D (three spatial dimensions plus time).The applications of interest are in energy storage and conversion. In particular, we are interested in developing solid state electrolytes for Li-ion batteries and battery separators.

Related Publications

- Rajas Sudhir Shah, Steven Bryant, Milana Trifkovic (2020)."Microstructural Rearrangements and Their Rheological Signature in Coarsening of Cocontinuous Polymer Blends." In: Macromolecules. doi:10.1021/acs.macromol.0c01688

- Shohei Yoshida, Milana Trifkovic (2020). “Unraveling the Effect of 3D Particle Localization on Coarsening Dynamics and Rheological Properties in Cocontinuous Polymer Blend Nanocomposites.” In: Macromolecules. doi:10.1021/acs.macromol.9b01437

- Kedzior, Stephanie A. et al. (2019). “In situ monitoring of the morphology evolution of interfacially-formed conductive nanocomposite films and their use as strain sensors”. In: Journal of Colloid and Interface Science. doi:10.1016/j.jcis.2019.07.018

- Pervez, Syed Atif et al. (2019). “Fabrication of a Dendrite‐Free all Solid‐State Li Metal Battery via Polymer Composite/Garnet/Polymer Composite Layered Electrolyte”. In: Advanced Materials Interfaces. doi:10.1002/admi.201900186

- Hoseini, Amir Hosein Ahmadian et al. (2017). “Significance of interfacial interaction and agglomerates on electrical properties of polymer-carbon nanotube nanocomposites”. In:Materials and Design.issn: 18734197.doi:10.1016/j.matdes.2017.04.004

- Hoseini, Amir Hosein Ahmadian et al. (2017). “Tunable electrical conductivity of polystyrene/polyamide-6/carbonnanotube blend nanocomposites via control of morphology and nanofiller localization”. In:European Polymer Journal.issn: 00143057.doi:10.1016/j.eurpolymj.2017.08.037

- Huang, Sijia et al. (2016). “Controlling the morphology of immiscible cocontinuous polymer blends via silica nanoparticles jammed at the interface”. In:Macromolecules.issn: 15205835.doi:10.1021/acs.macromol.6b00212.

- Batch, Gibson L. et al. (2015). “Immiscible blend morphology after shear andelongation”. In:AIP Conference Proceedings1664.May 2015.issn: 15517616.doi:10.1063/1.4918470

- Trifkovic, Milana, Aaron T. Hedegaard, et al. (2015). “Stabilization of PE/PEOCocontinuous Blends by Interfacial Nanoclays”. In:Macromolecules.issn:15205835.doi:10.1021/acs.macromol.5b00354

- Thomassin, Jean Michel et al. (2014). “Poly(methyl methacrylate)/grapheneoxide nanocomposites by a precipitation polymerization process and their dielectric and rheological characterization”. In:Macromolecules.issn: 15205835.doi:10.1021/ma500164s

- Trifkovic, Milana, Aaron Hedegaard, et al. (2012). “Porous films via PE/PEOcocontinuous blends”. In:Macromolecules.issn: 00249297.doi:10.1021/ma300293v

- Trifkovic, M, Aaron Hedegaard, and Christopher Macosko (2011). PE/PEO Cocontinuous Polymer Blends with Application In Gas Separation Membranes". doi:10.2118/191609-ms