METHODS

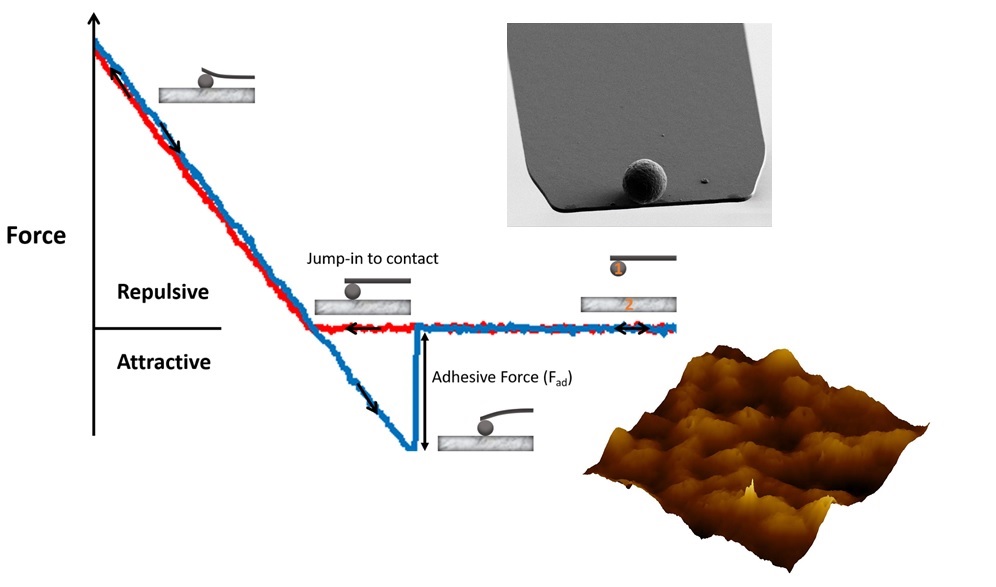

Colloidal probe atomic force microscopy (CP-AFM)

Colloidal probe atomic force microscopy (CP-AFM), is a powerful technique for the measurements of surface forces at microscopic scale. As oppose to conventional AFM, in CP-AFM the surface chemistry of the tip can be easily tuned in order to imitate the interface of interest. Also, knowing the exact geometry and topography of the tip is beneficial when quantitative analysis is aimed. Here in the Trifkovic’s research group, CP-AFM is utilized to measure polymer-nanoparticle interactions. To do so, a tip is approached to the substrate until it reaches a pre defined set point for the tip deflection and then is retracted. Upon retraction, the minimum value is recorded as the adhesive force which reflects the tip-substrate interactions at the interface. This value can be later used for both qualitative and quantitative analysis.

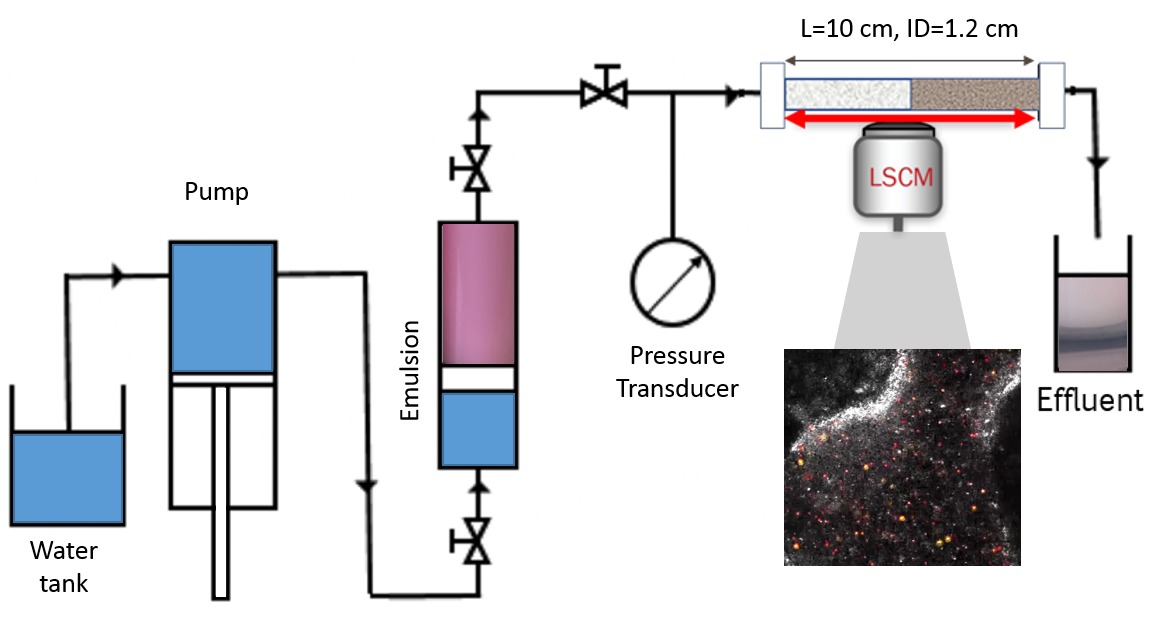

Visualization of complex fluid flow in porous media

The experimental setup includes a powerful 12K Vindum pump to drive the fluids, a small stainless-steel transfer vessel, an Omega 0-1000 psi pressure transducer, and a micro sand pack that is sketched below the setup figure. Incorporating laser scanning confocal microscopy (LSCM) allows for visual observation and characterisation of the events on the pore scale level, whereas with the pressure data the micro scale interactions can be correlated to the macro scale response. Currently, the fluids of interest are nanoparticle stabilized emulsions. Due to the desulfation of the CNCs, the particles are prone to networking, and thus the pressures generated while flowing are high and can range from 200 psi to 1000 psi. Having an engineering type pump incorporated into the system helps to achieve the needed high pressures to observe the interacting behaviour of the droplets between each other and with the porous media. Alongside, the micro model itself needs to be capable of withstand the pressures up to 1000 psi, which was made possible by using the PEEK type connections and matching the glass capillary diameter to the Teflon tubing diameter. Up to date, the effect of the sand grains surface wettability effect on the HCNC stabilized emulsion stability has been tested. The main observation is that hydrophilic surface, or unmodified sand, does not promote coalescence of the oil-in-water emulsion.