Production and Consumption of Biodiesel at the University of Calgary

Overview:

Running the backup power generators and grounds maintenance equipment at the University of Calgary consumes 36,900L of petroleum diesel annually. Using current market prices, this fuel usage costs an estimated $38,120 CAD and emits an estimated 34,300 kg of CO2 annually. The heavy cost, both economically and environmentally, presents a problem. The purpose of this project is to find a suitable solution for offsetting the financial and environmental burden of heavy diesel usage on campus, while creating a positive image for the University of Calgary through sustainable energy. Due to increasing climate concerns, it is important for UCalgary to begin reducing its carbon emissions, or to find methods of offsetting the emissions. Some methods of offsetting carbon emissions are by producing biofuels in order to use them for onsite energy production, sell them to third parties, or both.

In order to offset the cost of petroleum diesel, the cost of Waste Vegetable Oil removal, and the magnitude of carbon emissions, there exists an opportunity to utilize the WVO produced on campus. The conversion of oils into high quality biodiesel via transesterification is a proven method of upcycling with great successes at small scale university operations and large industrial processes alike. Such an operation can replace a substantial fraction of the petroleum diesel used on campus all while creating carbon offsets for the University. Other institutions have investigated the efficacy of converting waste vegetable oil (WVO) into biodiesel for on campus energy at various institutions, namely the University of British Columbia. Biodiesel itself has been used for generations to power diesel vehicles and equipment and has been used previously by the grounds crew at UCalgary to power some of its equipment. The production of biodiesel is simple enough for most individuals to create from home. To offset the cost of petroleum diesel, the cost of Waste Vegetable Oil removal, and the magnitude of carbon emissions, there exists an opportunity to utilize the WVO produced on campus. The conversion of oils into high quality biodiesel via transesterification is a proven method of upcycling with great successes at small scale university operations and large industrial processes alike. Such an operation can replace a substantial fraction of the petroleum diesel used on campus all while creating carbon offsets for the university.

Outcomes:

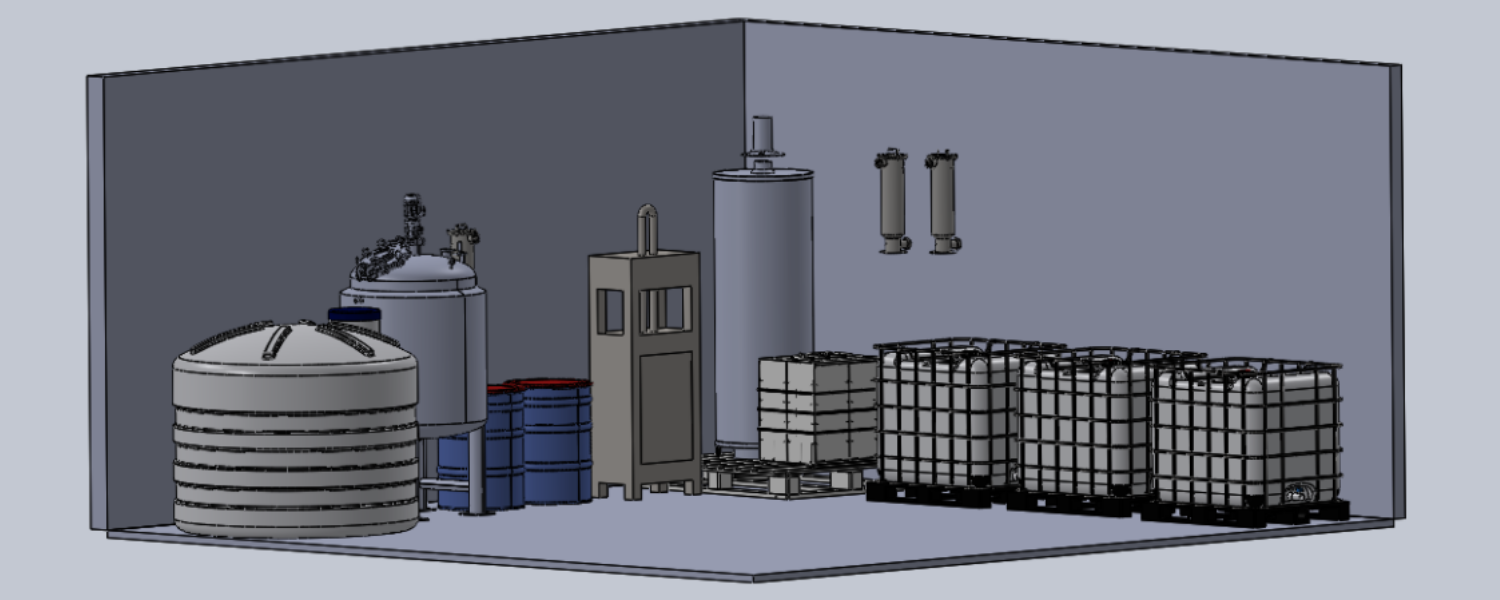

This project produced a conceptual design for the conversion process that offers economic and environmental benefits, all while accommodating the longevity of production and consumption systems currently on campus. After preliminary investigation and background research, the team found a vast number of detailed sources describing the pros, cons, and recommendations in biodiesel production. The process for this project was refined several times before finalization. This process will be a step-based batch process, beginning with a filtration pre-treatment of the WVO. The filtered oil will then be transferred to a tank in which a free fatty acid (FFA) esterification process will take place with methanol as the alcohol, catalyzed by sulfuric acid. Next, the oil transesterification process takes place with the same alcohol, this time with sodium hydroxide as the catalyst. This second process transforms the triglycerides within the WVO into combustible methyl-esters. This product is then mixed with water, which absorbs most of the contaminants, and then dried. The clean biodiesel product can then be transported to the consumption equipment for use.

The backup generators and grounds equipment will be able to run this biodiesel in a blend with petroleum diesel, which is decided to be a B20 blend or B5 blend, depending on the OEM warranty of the specific equipment. The number of the blend corresponds to the percent of biodiesel in the mixture, meaning that a B20 blend is 20% biodiesel and 80% petroleum diesel. Any excess biodiesel then can be sold to the public, for which three business case are outlined. The first case assumes salaries for operations staff, the second case assumes volunteers will be used to operate the system for 8 months of the year, and the third case assumes volunteers will be present to operate the system for 12 months of the year. The group also conducted an environmental analysis comparing the current environmental cost of using petroleum diesel to the environmental cost incurred by producing and using biodiesel in combination with petroleum diesel. With a minimum B5 blend or a maximum B20 blend, an emissions reduction is found to exist through the implementation of this project.

Next Steps:

Through the implementation of an on-campus biodiesel production system, the University of Calgary can reduce the financial cost, in addition to the carbon emissions of powering both the backup generators and the field maintenance equipment on campus. The group presented the findings from their project to UCalgary stakeholders, who are now investigating potential ways to implement the recommendations at the university.