PRELIM: The Petroleum Refinery Life Cycle Inventory Model

About PRELIM

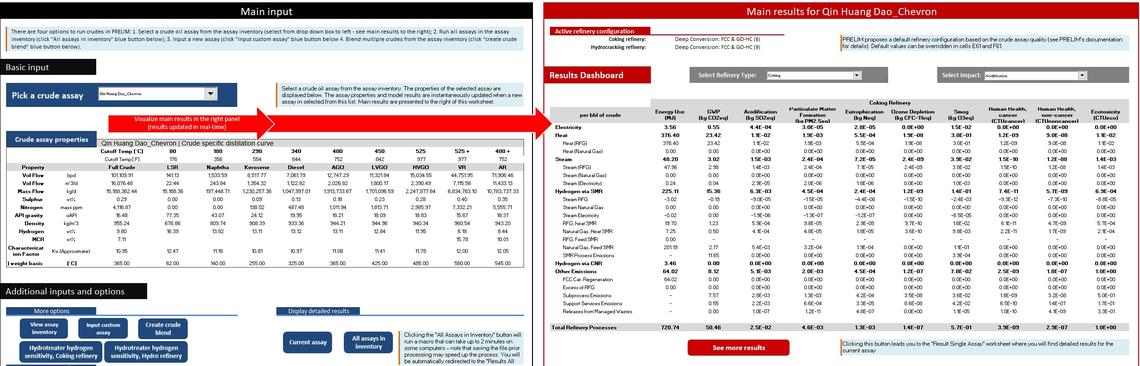

The Petroleum Refinery Life Cycle Inventory Model (PRELIM) is a mass and energy-based process unit-level tool for the estimation of energy use and greenhouse gas (GHG) emissions associated with processing a variety of crude oils within a range of configurations in a refinery. PRELIM aims to inform policy analysis by providing a transparent model including data, assumptions, and detailed results. The PRELIM model was built using Microsoft Excel to ensure transparency and maximum accessibility.

Copyright Statement

Copyright © 2022 Dr. Joule A. Bergerson

All rights reserved.

IMPORTANT INFORMATION

PLEASE READ AND ACKNOWLEDGE YOUR ACCEPTANCE OF THESE TERMS

a) You acknowledge that this website enables you to download, free of charge, both source and executable code for the Petroleum Refinery Life Cycle Inventory Model (PRELIM) together with relevant operating manuals (the “Software”).

b) You acknowledge that this Software is owned by Dr. Joule Bergerson of the University of Calgary (the “University”) and she has granted you permission to use the Software on the specific terms set out below. Your permission to use the Software can be revoked by Dr. Bergerson at any time without notice to you.

c) You acknowledge that this is experimental Software developed by Dr. Bergerson for the purpose of scientific research. It has not been designed or tested for commercial distribution. No maintenance or support is available for the Software.

d) You accept that the Software is offered to you on an “as is” basis, and neither Dr. Bergerson or the University is making any warranties of any kind regarding its performance, including merchantability, fitness for any purpose or non-infringement.

e) You understand that you are using this software entirely at your own risk. You agree that neither Dr. Bergerson or the University will be liable for any direct, indirect, special, incidental or consequential damages resulting from your use, misuse or inability to use this software, even if Dr. Bergerson or the University has been advised of the possibility of such damages.

f) You may modify, copy and distribute the software to third parties subject to the following conditions:

i) The Software and any modifications must be distributed free of charge, must contain an acknowledgment of the copyright of Dr. Bergerson, and must require acceptance by the user of the same license terms set out in this license;

ii) A copy of any modifications to the Software must be delivered to Dr. Bergerson for her use under the same license terms set out in this license

Models and Documentation

- PRELIM model v1.5.1 - Model (released Dec 6 2021) [XLSM]

- Updates in v1.5.1: Fixed the Custom Assay section on the Expert Input tab by enabling automatic calculations for Volume Flow and API.

- PRELIM model v1.5 - Model (released Oct 4 2021) [XLSM]

- PRELIM model v1.5 - Documentation (released Oct 4 2021) [PDF]

- PRELIM model v1.4.1 - Model (released June 20, 2021) [XLSM]

- Updates in v1.4.1: Fixed octane and cetane number calculations on the Expert Input tab. Fixed the hydrogen content calculations of heavy fuel oil. Fixed VDU product LVGO specs calculation errors.

- PRELIM model v1.4 - Model (released May 12, 2020) [XLSM]

- PRELIM model v1.4 - Documentation (released May 12, 2020) [PDF]

- PRELIM model v1.3 - Model (released May 5, 2019) [XLSM]

- PRELIM model v1.3 - Documentation (released May 5, 2019) [PDF]

- PRELIM model v1.2.1 - Model (released December 8, 2017) [XLSM]

- PRELIM model v1.2.1 - Documentation (released December 8, 2017) [PDF]

PRELIM Publications

1) Sleep, S., Dadashi, Z., Chen, Y., Brandt, A. R., MacLean, H. L., & Bergerson, J. A. (2021). Improving robustness of LCA results through stakeholder engagement: A case study of emerging oil sands technologies. Journal of Cleaner Production, 281, 125277.

2) Guo, J., Orellana, A., Sleep, S., Laurenzi, I. J., MacLean, H. L., & Bergerson, J. A. (2020). Statistically enhanced model of oil sands operations: Well-to-wheel comparison of in situ oil sands pathways. Energy, 208, 118250.

3) Sleep, S., Guo, J., Laurenzi, I. J., Bergerson, J. A., & MacLean, H. L. (2020). Quantifying variability in well-to-wheel greenhouse gas emission intensities of transportation fuels derived from Canadian oil sands mining operations. Journal of Cleaner Production, 258, 120639.

4) Jing, L., El-Houjeiri, H. M., Monfort, J. C., Brandt, A. R., Masnadi, M. S., Gordon, D., & Bergerson, J. A. (2020). Carbon intensity of global crude oil refining and mitigation potential. Nature Climate Change, 10(6), 526-532.

5) Young, B., Hottle, T., Hawkins, T., Jamieson, M., Cooney, G., Motazedi, K., & Bergerson, J. (2019). Expansion of the petroleum refinery life cycle inventory model to support characterization of a full suite of commonly tracked impact potentials. Environmental science & technology, 53(4), 2238-2248.

6) Motazedi, K., Posen, I. D., & Bergerson, J. A. (2018). GHG emissions impact of shifts in the ratio of gasoline to diesel production at US refineries: a PADD level analysis. Environmental science & technology, 52(22), 13609-13618.

7) Motazedi, K., Abella, J. P., & Bergerson, J. A. (2017). Techno–economic evaluation of technologies to mitigate greenhouse gas emissions at North American Refineries. Environmental science & technology, 51(3), 1918-1928.

8) Cooney, G., Jamieson, M., Marriott, J., Bergerson, J., Brandt, A., & Skone, T. J. (2017). Updating the US life cycle GHG petroleum baseline to 2014 with projections to 2040 using open-source engineering-based models. Environmental science & technology, 51(2), 977-987.

9) Laurenzi, I. J., Bergerson, J. A., & Motazedi, K. (2016). Life cycle greenhouse gas emissions and freshwater consumption associated with Bakken tight oil. Proceedings of the National Academy of Sciences, 113(48), E7672-E7680.

10) Abella, J. P., & Bergerson, J. A. (2012). Model to investigate energy and greenhouse gas emissions implications of refining petroleum: Impacts of crude quality and refinery configuration. Environmental science & technology, 46(24), 13037-13047.